In the bustling urban landscape of New York City, concrete surfaces play an essential role in both functionality and aesthetics. From sidewalks to driveways, patios to industrial floors, the durability of concrete is of paramount importance. However, the ever-changing seasons in New York present unique challenges for maintaining concrete surfaces that can withstand the test of time.

One company that has taken these challenges head-on is Southside Concrete Polishing. Hailing from the heart of New York, this dedicated company has not only mastered the art of concrete resurfacing but has also become a trusted name in ensuring the longevity and resilience of concrete surfaces throughout the city’s diverse seasons.

Let’s delve into the seasonal challenges faced by concrete surfaces in New York and the essential steps property owners can take to ensure durable concrete resurfacing. Join us as we explore the expertise of Southside Concrete Polishing and uncover the strategies and techniques they employ to combat the city’s harsh winters, hot summers, and everything in between. Whether you’re a homeowner, business owner, or property manager, this comprehensive guide will empower you to make informed decisions about your concrete surfaces, helping you maintain their integrity no matter what the weather brings.

Understanding New York’s Seasonal Challenges

New York City experiences a climate characterized by stark seasonal variations, presenting both opportunities and challenges for concrete surfaces. Understanding the climate is crucial for maintaining these surfaces effectively.

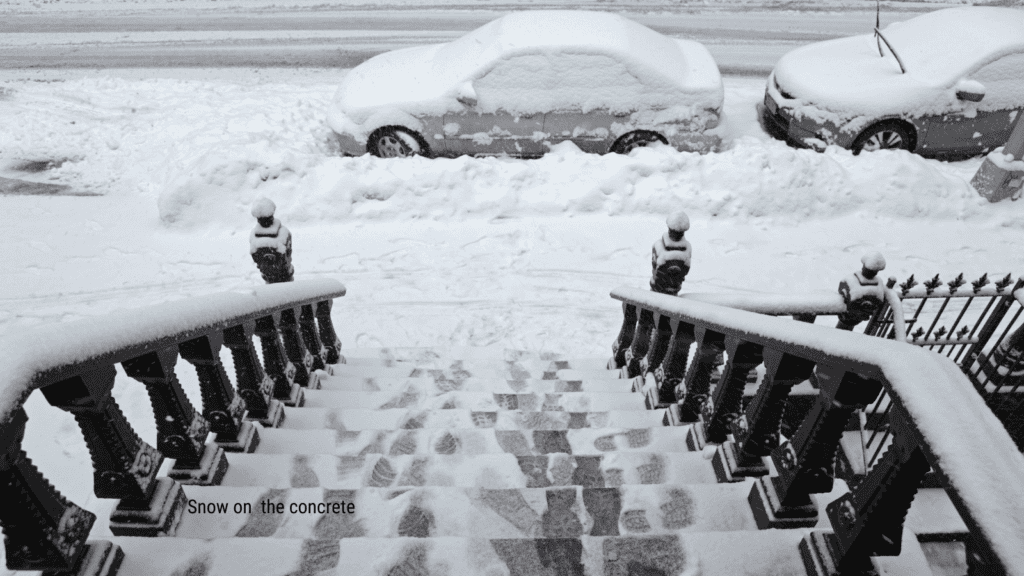

- Harsh Winters with Snow and Ice:

- New York winters bring sub-zero temperatures, heavy snowfall, and ice accumulation.

- These conditions can lead to freeze-thaw cycles, causing concrete to expand and contract, leading to cracks and damage.

- Snow and ice removal practices can also impact the integrity of concrete.

- Hot and Humid Summers:

- Summers in the city are marked by high temperatures and humidity.

- Prolonged exposure to heat can cause concrete to expand, potentially leading to surface cracks and degradation.

- Humidity can affect curing times and the adhesion of resurfacing materials.

The Toll of Freeze-Thaw Cycles on Concrete

Freeze-thaw cycles are a significant concern for concrete in New York. When water penetrates the surface and then freezes, it expands, creating internal pressure within the concrete. As the ice thaws, the pressure is released, causing microcracks and surface damage. Over time, this process can compromise the structural integrity of concrete surfaces.

The Significance of Proper Maintenance in the Face of Seasonal Challenges

Proper maintenance is paramount to mitigate the impact of New York’s seasonal challenges on concrete surfaces. Neglecting maintenance can lead to costly repairs and a shortened lifespan for your concrete. This article will explore proactive strategies and techniques to protect and preserve your concrete surfaces year-round.

Choosing the Right Materials for Resurfacing

Selecting the right materials for concrete resurfacing in New York City is a critical decision, given the city’s fluctuating seasons. Three primary resurfacing materials to consider are overlays, coatings, and sealants, with epoxy coatings being a standout option.

Overlays offer versatility and aesthetics. They are a thin layer of concrete applied over existing surfaces, customizable to mimic various materials like stone or tile. Overlays are excellent for enhancing the appearance of patios, driveways, and pool decks.

Epoxy coatings are notable for their durability and protective qualities. These coatings form a strong, seamless layer over concrete surfaces, resisting stains, chemicals, and UV damage. Ideal for high-traffic areas, garages, and basements, epoxy coatings not only provide resilience but also offer customization options in terms of colors and finishes.

Sealants are vital for safeguarding outdoor concrete surfaces in New York’s challenging climate. They create a protective barrier against moisture, preventing damage from freeze-thaw cycles and enhancing overall longevity. Sealants are especially crucial for driveways, sidewalks, and exterior concrete surfaces.

Preparing Concrete Surfaces

Before embarking on any concrete resurfacing project, it’s crucial to prepare the existing concrete surface properly. Neglecting this step can lead to poor adhesion, uneven finishes, and a shorter lifespan for the resurfacing work. In this section, we’ll explore the essential steps involved in preparing concrete surfaces for resurfacing.

Surface Cleaning and Preparation for Resurfacing

- Cleaning: Begin by thoroughly cleaning the concrete surface. Remove any dirt, debris, or loose material using a power washer or stiff broom. For stubborn stains, consider using a concrete cleaner. A clean surface ensures better adhesion of the resurfacing materials.

- Repairing Surface Imperfections: Inspect the concrete for cracks, spalling, or other imperfections. Address these issues by filling cracks with appropriate filler compounds and repairing damaged areas. Properly repaired surfaces ensure a smoother and more durable resurfacing outcome.

Repairing Cracks and Damage Before Resurfacing

- Crack Repair: Cracks in concrete can allow moisture to penetrate, leading to further damage. Use crack repair products compatible with the resurfacing material to fill cracks effectively. Ensure the repaired cracks are level with the surface.

- Patching and Leveling: For deeper damage or areas with significant wear, consider using patching compounds to level the surface. This step creates a uniform canvas for resurfacing and prevents uneven results.

- Importance of Addressing Underlying Issues (e.g., Drainage Problems)

Before proceeding with resurfacing, it’s essential to address any underlying issues that may have contributed to the deterioration of the concrete. Poor drainage, for example, can lead to standing water, which can accelerate surface degradation. Ensure that drainage systems are functioning correctly to prevent future damage.

Proper Resurfacing Techniques

Resurfacing concrete is a multi-step process that, when executed correctly, can yield durable and aesthetically pleasing results. This section outlines the key steps and best practices for achieving a smooth and long-lasting resurfaced surface.

Step-by-Step Guide to Concrete Resurfacing

- Surface Priming: Apply a suitable primer to the prepared concrete surface. The primer enhances adhesion between the existing concrete and the resurfacing material.

- Mixing Resurfacing Material: Follow the manufacturer’s instructions for mixing the chosen resurfacing material. Ensure consistency in the mixture to achieve a uniform finish.

- Application: Apply the resurfacing material evenly using the recommended tools, such as trowels or squeegees. Pay attention to thickness guidelines to achieve the desired thickness.

- Smoothing and Finishing: Work the resurfacing material to create a smooth, level surface. Depending on your design preferences, you can add textures or patterns during this phase.

Best Practices for Achieving a Smooth and Durable Surface

- Work in Sections: Divide larger areas into manageable sections to ensure consistent application and finishing. This prevents the material from drying prematurely.

- Curing: Properly cure the resurfaced concrete as per the manufacturer’s recommendations. This step is crucial for achieving the desired strength and durability.

- Sealing: Consider applying a concrete sealer once the resurfaced surface has fully cured. Sealers enhance protection and longevity, especially in high-traffic areas.

The Role of Experienced Contractors in Ensuring Quality Resurfacing

While DIY concrete resurfacing is possible, it’s often best left to experienced contractors who understand the nuances of the process. Professional contractors have the expertise and equipment to deliver a flawless finish and ensure that all preparation and application steps are executed correctly.

By following these preparation and resurfacing guidelines, you can enhance the longevity and performance of your concrete surfaces, effectively addressing the seasonal challenges faced by concrete in New York City’s dynamic climate.

Seasonal Maintenance

Concrete surfaces in New York City are subjected to diverse seasonal challenges, demanding regular upkeep to preserve their integrity. In this section, we explore practical tips and considerations for seasonal maintenance to ensure your concrete surfaces remain robust throughout the year.

Winter Maintenance Tips

- Snow and Ice Removal: During winter, prompt snow and ice removal is essential. However, it’s crucial to use snow removal tools and de-icing agents that won’t harm the concrete surface. Avoid harsh chemicals like rock salt, which can accelerate concrete deterioration. Instead, opt for calcium chloride or magnesium chloride alternatives.

- Protecting Against Salt Damage: If salt has been used extensively in your area, consider sealing your concrete surfaces in the fall. Sealing provides an additional layer of protection against salt damage and moisture infiltration.

Summer Maintenance Tips

- Preventing Heat-Related Issues: In hot and humid summers, concrete surfaces can expand and potentially crack. Provide shade or use reflective materials to reduce surface temperature. Regularly watering concrete surfaces can also help dissipate heat.

- Regular Cleaning and Sealing: Periodic cleaning of your concrete surfaces with a mild detergent and water can prevent dirt buildup and staining. Reapply sealant as needed to maintain the protective barrier, ensuring resistance to moisture and UV damage.

Long-Term Maintenance Strategies

Maintaining the longevity and durability of concrete surfaces in New York City requires more than just seasonal care; it demands a comprehensive long-term strategy.

Importance of Regular Inspections

- Frequent Assessments: Schedule regular inspections of your concrete surfaces to identify early signs of wear and tear. Look for cracks, spalling, or areas of deterioration that may need attention.

- Drainage Evaluation: Continuously monitor the drainage around your concrete surfaces. Proper drainage prevents water accumulation, reducing the risk of moisture-related damage.

Identifying Signs of Wear and Tear

- Crack Management: Address cracks promptly. Smaller cracks can be repaired with suitable fillers, while larger structural issues may require professional intervention.

- Surface Cleaning: Regularly clean your concrete surfaces to remove dirt, debris, and contaminants. Keeping the surface clean can prevent staining and deterioration.

Scheduled Resealing and Maintenance

- Resealing: Depending on the type of sealant used, plan to reseal your concrete surfaces every few years. This protective layer enhances resistance to moisture, UV rays, and staining.

- Maintenance Contracts: Consider entering into maintenance contracts with professional concrete maintenance companies. At Southside Concrete Polishing, we can provide regular cleaning, sealing, and repairs to extend the lifespan of your concrete surfaces.

By implementing these seasonal and long-term maintenance strategies, you can ensure that your concrete surfaces in New York remain not only resilient but also a durable and lasting asset for your property, withstanding the challenges posed by the city’s ever-changing climate.

In the ever-changing landscape of New York City, where the seasons bring extreme weather fluctuations, maintaining resilient concrete surfaces is paramount. We hope you have learned some valuable insights into understanding and conquering the challenges posed by New York’s climate.

At Southside Concrete Polishing, we take pride in being your partner in this endeavor. From the durability of epoxy flooring to the versatility of concrete overlays, we excel in preserving and enhancing concrete surfaces. With our waterproofing solutions and pressure washing services, we stand as champions of concrete maintenance.

To fortify your concrete surfaces and transform them into enduring icons of durability and aesthetics, consider contacting us at Southside Concrete Polishing. Our expertise is your assurance of surfaces that not only withstand New York’s seasons but also exude lasting beauty in the heart of the city.

Share This Post